Connected systems to control the chaos

ACT Hub connects to HVAC and refrigeration systems, turning their data into real-time performance insights, automated equipment control and optimized operations.

With ACT Hub you get the insight of an energy manager, the technical expertise of a maintenance manager, and the strategic analysis of an asset manager watching everything 24/7.

ACT Hub Benefits in Action

ACT Hub’s built-in analytics look deeply at how your systems are running, keeping you in the know, and at least one step ahead of anything that could interrupt operations.

- Extend asset life and better system performance

- 24/7 visibility into actual equipment performance

- AI-powered diagnostics and repair validation

- Automated work orders to keep teams focused and productive

A complete package for all facility specialties

The ACT Hub platform delivers data and recommendations in specific operational categories so small teams can divide and conquer with ease.

Explore use cases by function here.

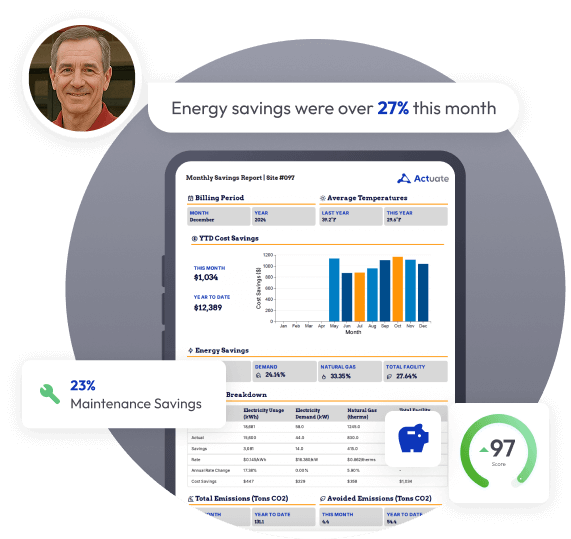

The EnergyMGR app provides multi-location businesses with this critical function at a fraction of the price of a full-time employee.

EnergyMGR makes it easy to understand energy use, identify savings opportunities, and pinpoint investments that yield long term sustained savings.

Key energy management features ACT Hub EnergyMGR:

- Uses energy meters to measure facility and equipment energy use and demand.

- Accurately predicts energy consumption and peak demand so utility bills are never a surprise.

- Delivers digital twin energy models to identify anomalies, efficiency drift and performance issues.

- Learns your facility then optimizes set points and run times for comfort and efficiency.

- Automates utility rate analysis including Time of Use rates

- Scope 2 Emissions tracking and broad analytics model-based savings reports.

ACT Hub FacilitiesMGR brings a robust building management toolset to owners, executives and operations managers without requiring specific existing equipment or expensive retrofits.

By connecting to and analyzing operational data, FacilitiesMGR provides insight into equipment performance and makes automatic adjustments based on equipment conditions, optimizing and extending the life of costly HVACR systems.

Key facilities management features of ACT Hub FacilitiesMGR:

- Data analytics for scoring equipment age and current value against replacement costs

- Detailed equipment data including nameplates, specifications, O&M manuals and service bulletins

- Real-time equipment performance monitoring

- Lifecycle cost management

- Predictive maintenance

- CapEx planning

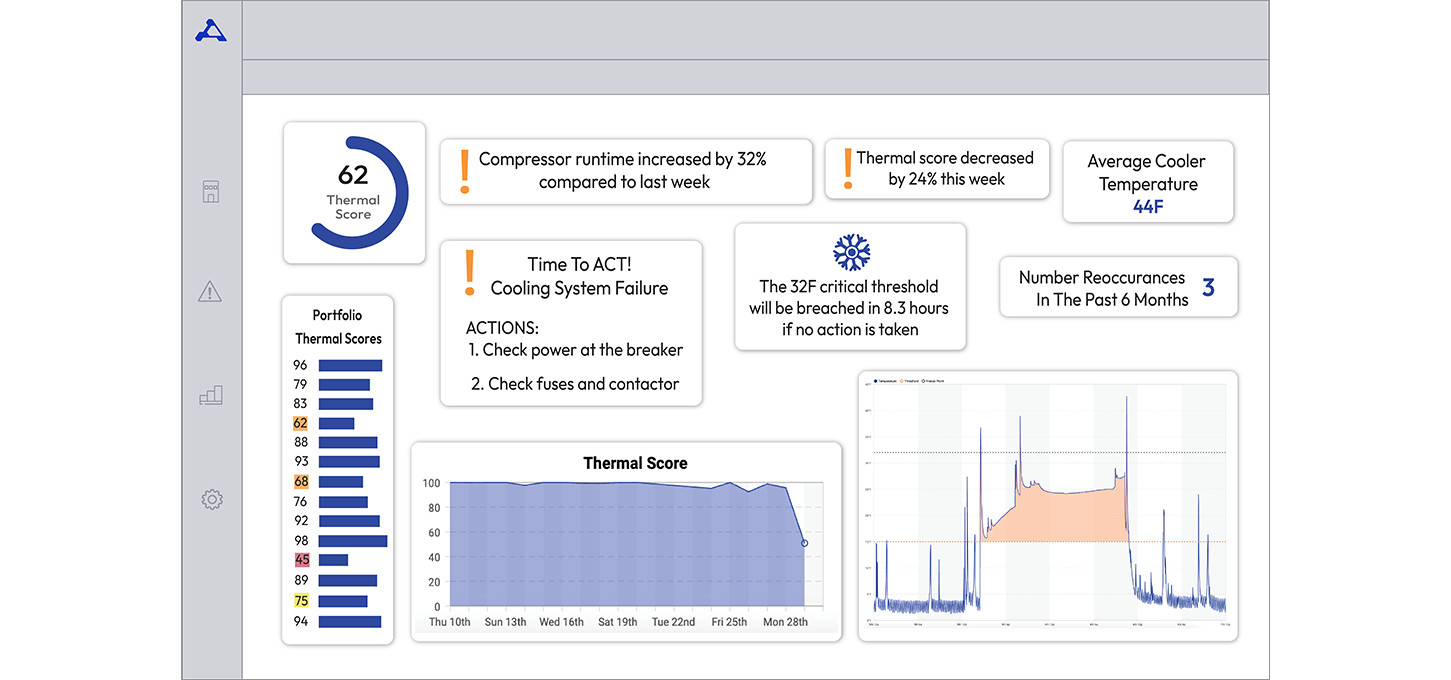

MaintenanceMGR augments team capability to reduce truck rolls, eliminate second trips, optimize labor cost, and provide visibility and performance data remotely.

Through connected data, 24/7 monitoring and ACT Hub’s root cause analysis engine, clear actions are communicated using plain language, making maintenance predictive, proactive and productive.

Key facilities management features of ACT Hub MaintenanceMGR:

- Prioritizes maintenance tasks based on cost and impact.

- Automates work orders with relevant real-time data, repair history summaries and links to equpiment specs.

- Monitors 24/7 and in real time to constantly analyze system performance and deliver real-time critical alerts.

- Delivers diagnostics with Root Cause Analysis and detailed actions for resolution.

- Predicts failures to avoid costly outages and service disruptions.

- Enhances traditional preventive maintenance cycles with live monitoring and detailed reporting.

AssetMGR provides a suite of tools to visualize, manage, and analyze HVAC-R assets with powerful condition based scoring and KPIs.

ACT Hub provides field access to equipment information and specifications, empowering teams to make better data-driven decisions, fundamentally changing how systems ar e managed, operated, and maintained.

Key asset management features ACT Hub AssetMGR:

- Supports CapEx planning using equipment scoring based on performance, efficiency and comfort

- Offers comparative cost modeling for new vs. repaired equipment.

- Delivers condition-based and predictive maintenance o to keep systems running.

- Extends asset life through better maintenance and operations programs.

- Makes lifecycle costs manageable and predictable for better capital planning.

- Enables end-of-life monitoring to keep systems running efficiently until absolutely necessary to upgrade.

Trends in Facilities Management and Energy Efficiency

Download our white paper How AI is Reshaping Restaurant Facilities Management.